+38(050) 394-07-63

COGENERATION PLANTS

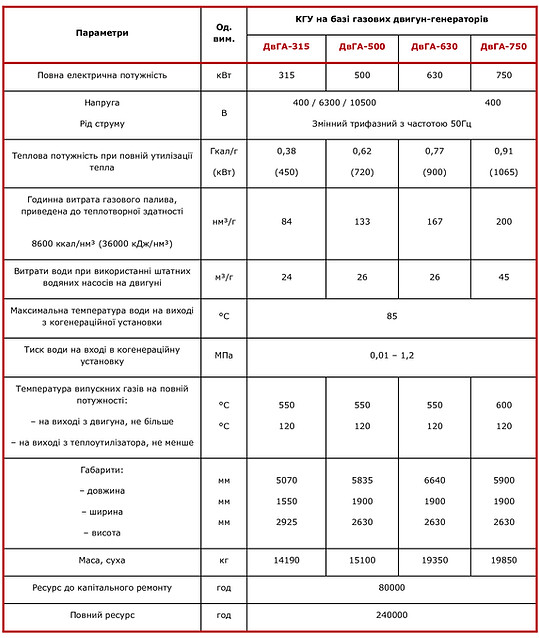

Cogeneration plants (CGU) are based on gas engine generators and diesel generators with the utilization of heat from the gas-air mixture after the turbocharger, cooling water, lubricant, and engine exhaust gases.

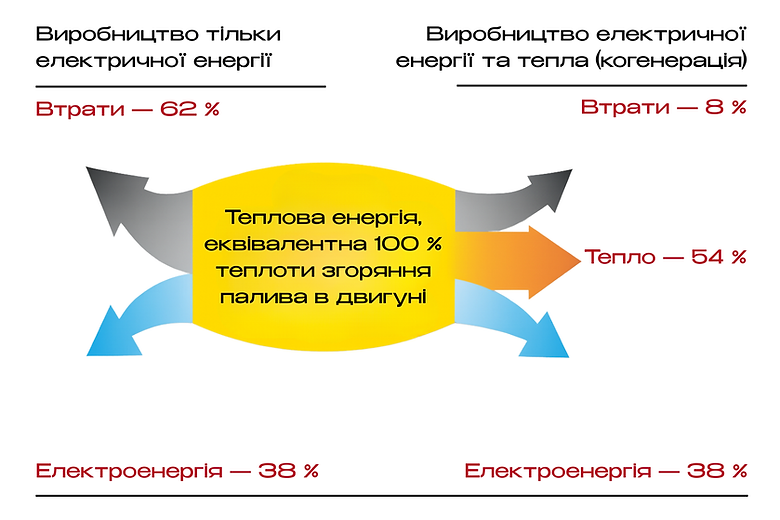

Due to the additional thermal energy generated in the water-heating heat exchanger-utilizer included in the delivery, an increase in total power by 2.5 times, an increase in efficiency to 92% and a 40% reduction in fuel consumption compared to the traditional separate generation of thermal and electrical energy are achieved.

Comparative balance of a cogeneration plant

As fuel in the CHP, both traditional types of fuel are used: diesel fuel, natural gas, and alternative types: vegetable oils, biodiesel, biogas, generator gas, associated petroleum gas, mine gas methane, and other combustible gases with a lower calorific value of 1200 kcal / m3 and a pressure on the supply line to the engine of 0.01-0.4 MPa (0.1-4 kgf / cm2). The low cost of electrical and thermal energy produced by the CHP allows you to get a profit sufficient to recoup the capital costs of its implementation within 2-3 years.

The CHP does not require large areas to be located, which allows it to be installed close to the end consumer, without disrupting existing systems and large capital expenditures.

The proposed delivery options for CHP units are: for installation in existing and adapted premises or in newly built buildings, as well as complete with a noise and heat-insulating easily assembled shelter.

KSU based on 2 DvGA-500

in a collapsible shelter

KSU based on DvGA-500

in an easily assembled shelter

KSU based on DvGA-500

in the new building

CHP based on 2 DvGA-630 in an adapted building of a former heating station

Our engine-generators have proven themselves over the years in operation in various natural and climatic conditions in more than 40 countries around the world.

FIELD OF APPLICATION

For combined production of electricity and heat in autonomous or parallel operation with external networks:

When operating low-yield natural gas fields of industrial importance

At enterprises that had carbon-rich waste, using pyrolysis gas and biogas from MSW landfills

In the heat and power industry using natural gas, generator gas and biogas from biomass;

In various industries as a backup power supply using diesel fuel.

In the agro-industrial complex, livestock farming, poultry farming, at a fat factory and at food processing plants, using biogas and fuels based on vegetable oils;

At oil production facilities using associated petroleum gas

In coal mining areas using coal mine gas

At metallurgical plants using ferroalloy, coke oven, and blast furnace gases

Our cogeneration plants with an electrical capacity of 500 and 630 kW correspond to the code 27.11.32-35.01 "Combined cycle gas piston machines with a capacity of 7.5 kV∙A with a fuel heat utilization factor of 83% and above" are included in the Industry Classifier of Energy-Saving Products, approved by the order of the National Energy Regulatory Commission of Ukraine dated 10.12.2010 No. 159 (since 2013 - by the order of the National Energy Regulatory Commission of Ukraine dated 21.06.2013 No. 79)